Finally, I took apart the fixation and proceeded with the root cause analysis of the failure. My fixation design was flawed, as the lateral compression stresses cannot be taken by the short stem from the original down tube of the donor bicycle. I totally underestimated the level of those localized stresses. In the next two pictures the extent and mechanism of the damage can be seen.

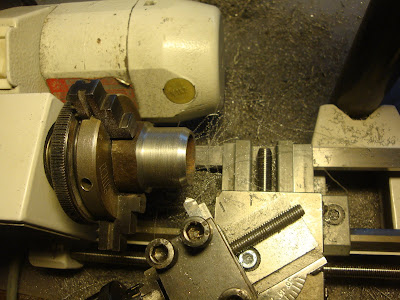

The plan was to reinforce the tube with an inner plug. The same plug is to be used as a tool to stretch the cross section of the tube back to round. Below you can see the plug being turned in the Unimat out of a massive steel bar from an old spark plug tool. A conical shape was machined in the tip to open up the deformed tube cross section.

Fitting the plug into the tube.

Cross section back to perfect round shape. At this point, as I noticed that it was not very difficult to bring the tube back to shape again, I realized that the reinforcement should have been planned in the first place.

Even if it did not fail yet, I decided to apply a similar reinforcement to the rear fixation support. The only difference is that for the front plug I will drill again the hole for the transversal tube; for the rear fixation I carved a notch in the plug in order to mount it without ondoing the brazings in the fixation that did not fail.

Additionally, I decided to apply a set of lateral brackets to further reinforce the front fixation point. I started with a rectangular piece of a 1.5 mm steel plate and shaped the curve around a tube with the same diameter as the donor bike's down tube.

A little bending here and there, fluxed... and ready to braze.

Here is the final result. It might not look very delicate, but solid it is.

And after a couple hundred kilometers, it is still in perfect condition.